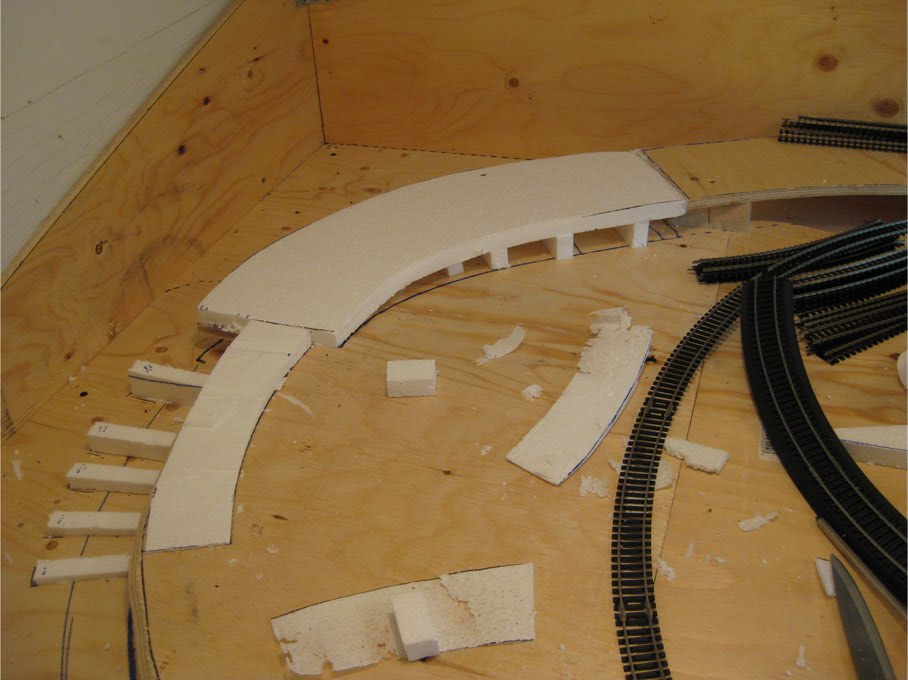

After a week, I finally completed my trestle. I built it using 1/4” and

3/8” square doweling rod purchased from a local hardware store. I first

traced on a large sheet of paper the track curve, as well as the location of

the tracks that would pass below. From this, I determined the measurements

as well as the location of each pier.

I built the deck of the trestle directly onto the drawing that I had made,

using this as an exact guide for placing the pieces. This was the best

option to keep everything accurate. The piers had to be on a sharp angle due

to the two tracks passing below so extra support had to be given to the

trestle deck in some areas. I finished the piers with 1/16" cross supports

as well as a deck for the 18" radius track to sit on. Even thought this is

not the most prototypical trestle, it still looks good on the layout and

fits the track perfectly.

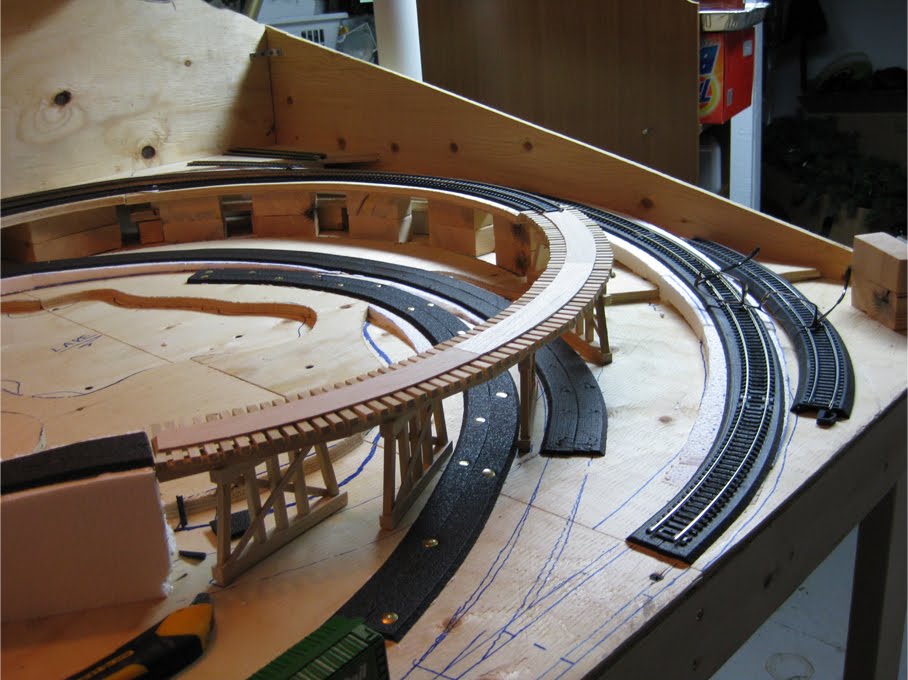

By this time I have placed all of my track bed with the exception of the

front staging area. I just want to be sure of my turn out positions before I

glue anything down permanently. You can finally get a good idea of how my

layout is going to look.

On my last day off, I added the trackbed for the upper mountain tunnel

lines. The outer track is part of the main oval line, which will descend

down to the front staging area. The second ascends up from the track

crossing in the center of my layout to the raised area at the rear of the

layout. This line and the main line run together in one tunnel portal. I

have also laid the track through the lower tunnel portal . I completed this

so I wouldn't have to work around the upper sections of track in the

future.

This wraps up my Canada Day long weekend. My plan for the following week

will be to get a good start on the large wooden trestle.

On Saturday I decided to tackle the bridge that will carry both the oval

main line and figure-eight line of track in the rear section of the layout.

For this, I purchased a set of pier girders as well as a warren truss bridge

kit. With a little modification, I attached two bridge girders together

using a third girder.

When these were dry, I attached bridge sides of the warren truss kit to the

girder deck. I used a few scrap pieces of styrene to add additional support

to the trusses. The final look and design looks pretty decent. I placed the

bridge onto my layout and used foam shims on each end so it was level with

the track. I then finished with butting foam roadbed right up to the bridge

deck.

The bridge will still need to be painted to for some added realism, but

this will happen at a later time. I also had to add a foam extension to the

main line curve as shown in the photo below (under the 15 pound weight).

This extension was the result of a measuring mistake I made early in my

original planning. Thankfully this was an easy fix. Trackbed was also added

at this time to both tracks at the rear of the layout.

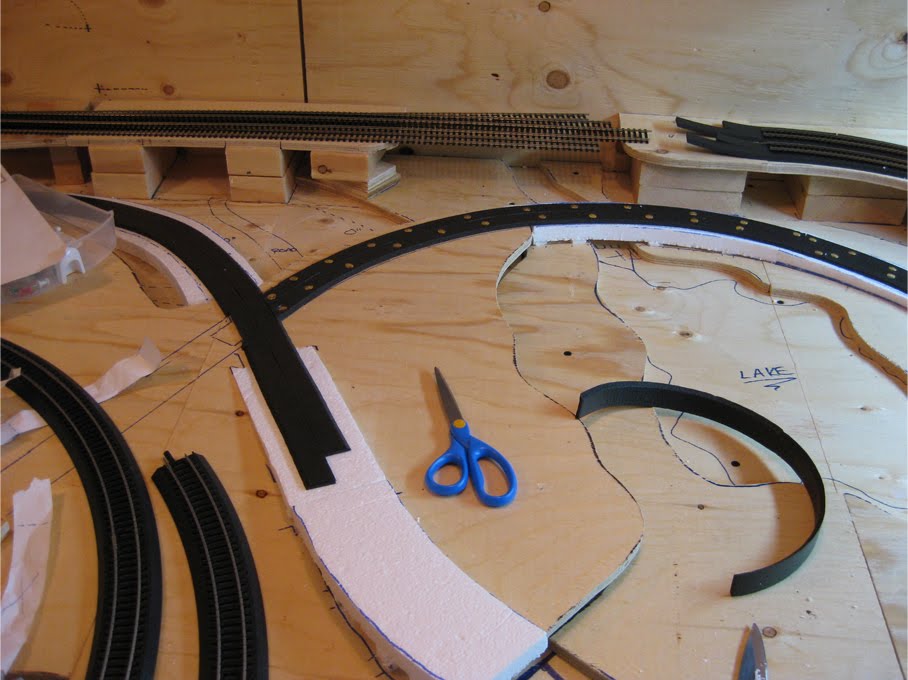

The next section that I wanted to complete was the stretch of track that

would travel down from the trestle, below the main line, and loop back into

the front switching are. This section will be part of a tunnel in the future

so I decided to complete it now before I did too much work on the tracks

above it. The foam roadbed was the first step after planning the track path.

Once again, I used thumb tacks to hold the roadbed in place while the glue

dried.

At this time I also installed the segment of roadbed for the section that

will travel from the front staging area, around the lake area and up onto

the mid-section of the layout. This will cross the part of track that

descends from the trestle at a 60 degree angle.

With July 1st this year being on a Thursday, my work decided to shut down

for IT upgrades on Friday as well, giving me a nice long 4 day long weekend

- plenty of time to make some serious progress on my model.

I first fixed my original ramps on the left side of my layout. I shaved

them down with a sharp knife and placed different sized risers underneath to

make them much more gradual and smooth. I also laid foam trackbed on the

right side of the layout leading up to the future trestle.

The second approach to the trestle is also constructed at this time. This

unfortunately is going to be the most challenging part of the layout as far

as track goes as the total grade here is about 11%. This however, is a risk that just needs to be taken for the sake of

the rest of the layout. I’m sure it will all work out in the end. For track

planning, I commonly used Bachman E-Z Snap-Track to plan where my actual

track and foam roadbed would go. This track works great as a moveable

template and grade planner when working with 18” radius curves.

Over the last month or so I have been building the ramps to allow the

tracks to go from one level of my benchwork to the next. I purchased 3/4”

sheets of Styrofoam and used this for each of the ramps. It took several

attempts to get them right as it's quite difficult to get a perfectly even

and level transition from one level to the next level. There are other

products available to make this process much easier, such as Woodland

Scenics foam risers, but I’m determined to use what I have!

The first ramp completed successfully is the right curve of the main line

oval. After hours of trying to get everything just right, it was time to lay

down the very first section of foam trackbed. I glued down one half at a

time in about 20” lengths. I used WeldBond multi-purpose glue and thumb

tacks to temporarily hold the track bed in place while it dried. Once the track bed was dry, I loosely placed 22” radius track to make sure

everything fit, which it did.

The main benchwork elevations are complete! To get the actual sections to

match my original planned elevation sections (which I marked out earlier on

the table), I first took large sheets of news print and laid them out to

cover the entire sections. The paper was thin enough that I could see the

lines I drew on the benchwork beneath it and thus traced the sections onto

the paper.

I then used the paper template to draw the elevated sections onto a new

sheet of plywood. Using a jigsaw, I cut the sections out. These all fit

perfectly on the table. I used scrap pieces of wood at varying heights to

support the new elevation sections depending on how high I needed them to

be.

The majority of the layout is raised up from the original table with only

the very front staging section at an elevation of 0. The back section is

raised 3 1/2” to allow for a double-mountain tunnel, as well as a bridge and

trestle. The left half of the layout is raised 1 1/2” and acts as an

elevated half way point for the descending track from the trestle and the

climbing track from the lake/swamp area. The top right area has a raised

section leading to the start of the future trestle.

Once my base table was completed, I re-applied the Atlas track templates

back onto the table so I had a good approximation of how my final track was

going to fit.

I then cut my side and back scenery walls to a size and shape that seemed

appropriate for what I was trying to accomplish. At this point I still am

not exactly sure what I am going to use for a backdrop, however I left

plenty of surface area if required later. I then simply screwed the pieces

onto the sides of my bench, using metal braces where the panels joined

together.

After the side and back panels were attached, I used the track templates to

plan the different elevations that were going to be required for the layout.

I visualized the different elevations I wanted and marked them out directly

onto the table. These sections will later be cut out on a separate piece of

plywood and attached with risers to their required heights.

After 2 weeks of planning, measuring, cutting, and measuring again, the

main bench is finally completed. The bench is actually two 4x4 tables which

bolt together with removable legs and frame. This allows it to be broken

down and removed from my basement (which is going to be a painful task if it

is to ever happen). I now have the base to start my layout.

After clearing out a good portion of my tiny basement back in February, I moved down my

future table top which I cut into four section so I could fit it down the stairs. I copied and cut out Atlas track templates and laid them out on the

plywood. I could now see exactly how the track would

eventually lay out and knew that my computer-designed track layout would

translate well to the 4 x 8 benchwork size. The templates also allowed me to see some

areas where adjustments needed to be made.

Construction began back in February of this year, so I have about 6 months

to catch up on. Over the next several days I will post my progress from

February 15th right up to today (July 16th, 2010). After that, I will post

often so things are always recent. I have also updated my blog pages listed

above, so please check them out for a bit of background information on this

project.