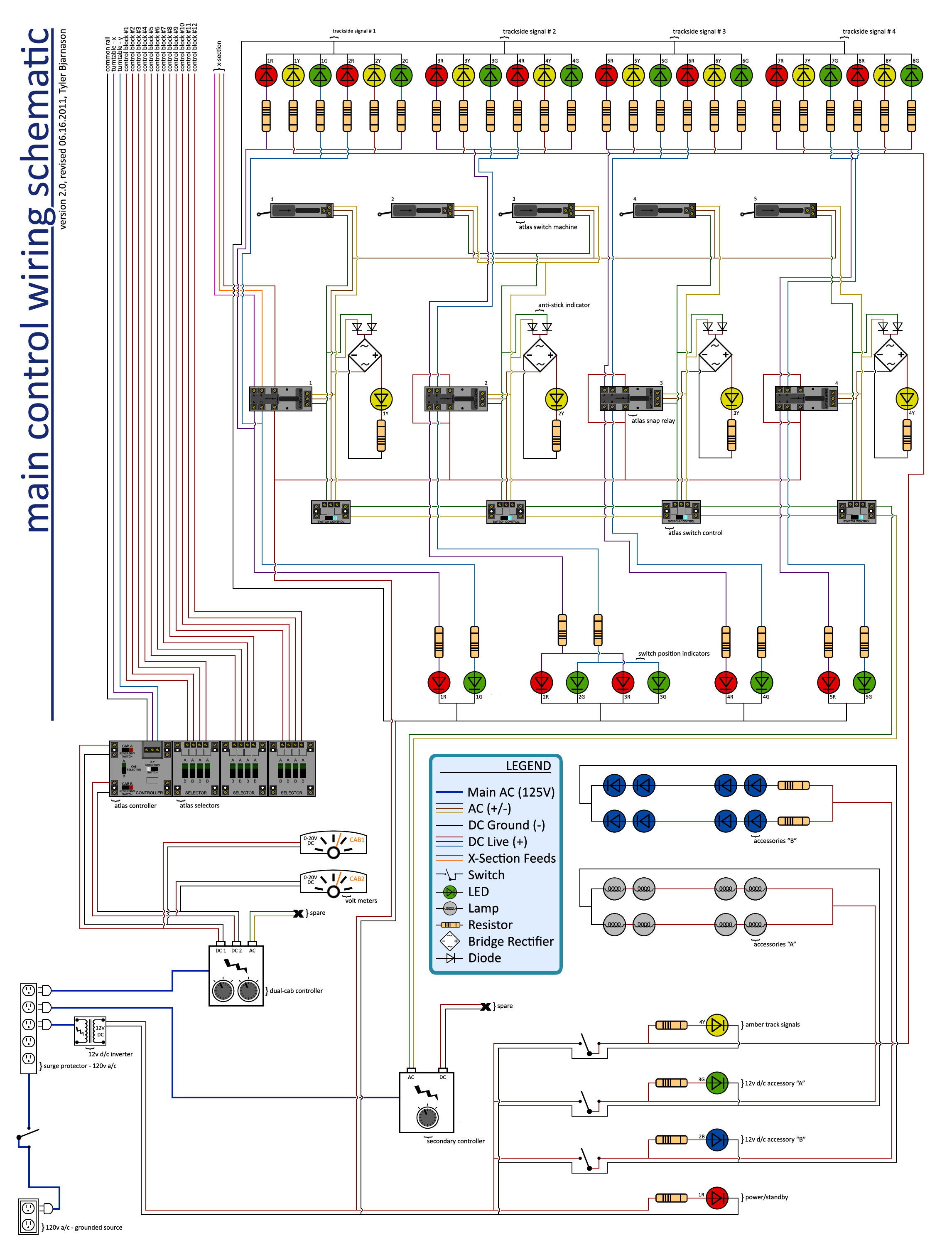

Since my last update, I have been working almost daily on my new control

panel. I have also finished the wiring plan and schematic for all of the

switches and electronics. The plan includes the wiring for the control

panel, all lighting and signals, switch machines, power blocks, and

under-table wiring. I have been working and modifying this electrical plan

for quite some time now and though it looks quite complex, it’s actually

quite simple. It just looks like a lot because it shows absolutely every

circuit. Some of this is already wired, such as the under-table switches,

but the majority of it will be in my control panel.

As for the control panel, it has been quite a learning experience with a

lot of trial and error, blood and frustration. In the end however, the

almost-finished product turned out pretty good.

I planned the control panel to be a box-style panel, with all the lights

and switches on top and all wiring and electrical components stowed inside.

I decided to use 1/4” hardboard to construct the controller. Like always, I

first made a detailed plan on paper of what I wanted to build. This makes

things so much easier when it comes to construction. After drawing out the

panel pieces on the hardboard, I used a jigsaw to carefully cut them out. I

then glued them together with Weldbond white glue.

Once the glue had cured, I measured and cut out the holes for the voltage

meters. These meters will eventually monitor the CAB 1 and CAB 2 outputs

from my power pack. I decided to go with analog gauges instead of digital

ones for a more of a traditional look.

I was originally planning on painting my control panel, however I realized

that paint was not going to be enough to cover many of the imperfections. I

decided to cover the box with recycled black and wicker aluminum cladding

from a scrap yard. I was not able to bend the cladding well enough to cover

the box, so I cut individual pieces for all 5 sides.

Cutting holes through the cladding for the voltage meters proved to be

quite the challenge as I didn’t have the right tools to cut a perfect

circle. Instead, I used a small drill bit to drill several dozen holes

around the traced circle. I then re-drilled these holes with a larger bit

until the holes joined and the center circle fell out. With a bit of

modification and filing, it fit perfectly over the control box

holes.

Using PL Ultimate construction adhesive, I attached 1/2” steel L-molding to

the edges and corners of the panel, giving it a finished look. The finished

panel turned out better than I expected, though there are some noticeable

imperfections. At this time I also installed all of my Atlas switches on the

face of the control panel.

Next I installed the controller components onto the face of the panel using

small screws. For these, I used an Atlas Controller, three Atlas Selectors,

and four Atlas Switch Control Boxes. The Controller will allow me to reverse

direction on both CAB 1 and CAB 2, as well as select which CAB controls the

turntable. The selectors will control the twelve power blocks on my layout

and the four switch control boxes will switch the track turnouts. See the

Wiring Diagrams

page for detailed explanations of how all these components work.

The next item for construction was the display for the turnout positions as

well as the 13 track power blocks. I decided on two separate diagrams;

one for the overall layout and one for the turnout points. This kept the

diagrams much less cluttered and easy to understand. I cut frames for each

diagram out of 1/16” craft wood board and stained it dark ebony.

For the diagrams, I used digital vector images I created in Photoshop

instead of using the traditional tape method. I printed these images on

photo paper and glued them to the back of the wood frames. I then fastened

the frames to the face of the control panel with PL Ultimate adhesive. The

numbers on the diagrams correspond to the switch numbers and the power

blocks.

Next I drilled holes through the switch position diagram and installed my

LED lights which will indicate the switch positions; red for the turnout and

green for the main line. Switches 1-3 are all for the main line yard and

switch 4 is for the turnout to the turntable. I also drilled holes for the switch and accessory indicator lights, such as

layout and power LEDs.

The yellow LEDs at the top of each Atlas switch are for switch machine

overload protection. I’ve heard that Atlas switch controls sometimes stick

and will burn out switch machines so I added this little feature that will

indicate a stuck switch. The LED will light only for the moment that the

switch is pressed. If the switch sticks, the LED will stay lit, indicating

power overload. You can see how I wired these in the wiring schematic at he

bottom of this post.

Once everything was attached, I started to label all of the Atlas

controllers, switches and selectors. The numbers that were included with the

switches didn’t fit correctly nor did they look good, so I constructed my

own in Photoshop. I opted for a black background and white text, making them

blend perfectly with the Atlas switches. Once printed, I cut out each letter and number and stuck it to each switch

using double sided tape.

I will still need to label the rocker switches and some of the other LEDs

on the control panel, but I'm pretty happy with how this turned out so far.

The next step will be all of the wiring. The control panel will eventually

be mounted to a piece of plywood with the cab controller right beside it.

The final plan is to have the entire unit fold away under my layout when not

in use.