Since my last post, I’ve spent the majority of my time tuning my wiring and

track. I haven't made much structural progress, but I've spend a lot of

hours adjustments to my track to ensure my engines and rolling stock run as

smooth as possible. As this is my first layout, every aspect of this project

is a huge learning curve.

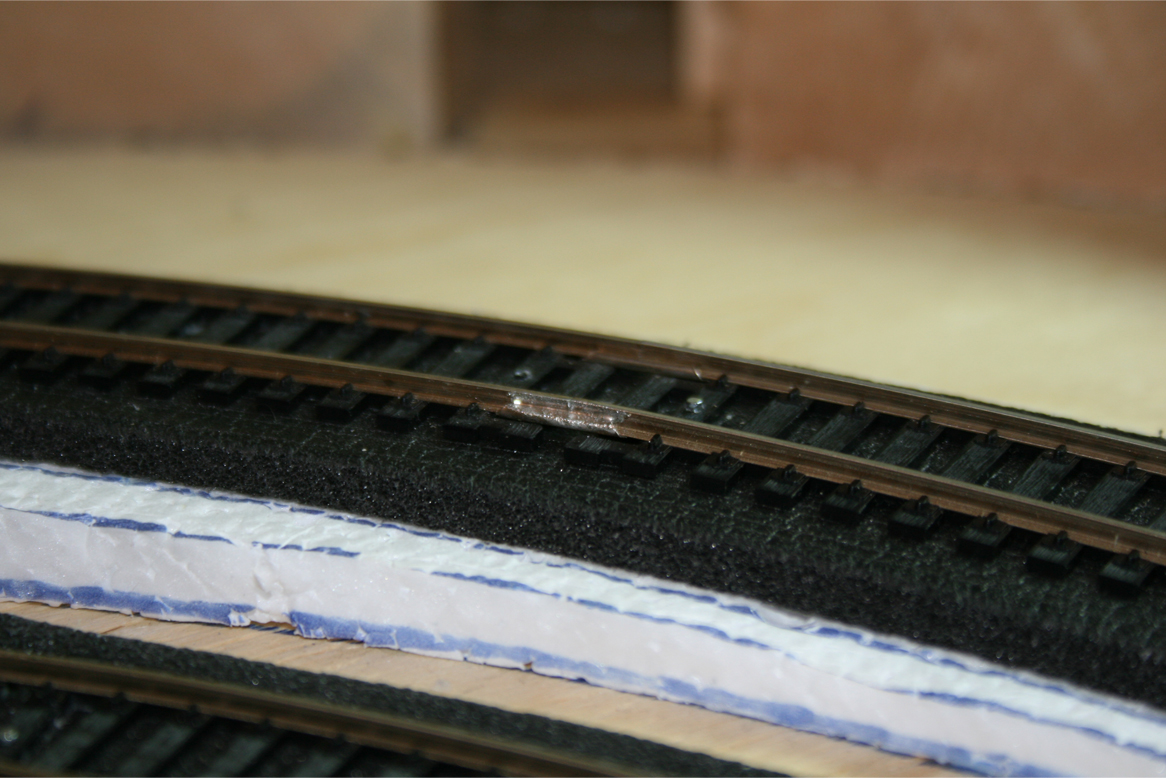

When I originally laid my track, I did not realize how extremely important

it was to ensure track was perfectly level, especially through curves and

grades. Even the smallest inconsistency in track level is often enough to

derail an engine. I found that these deviations were most common where two

pieces of track joined together. To solve this, I made sure both adjoining

pieces were perfectly level then soldered them together. I then lightly

sanded the joint until it was perfectly smooth. For areas where the actual

trackbed wasn’t level, I used thin foam shims under the track to keep the

track perfectly level.

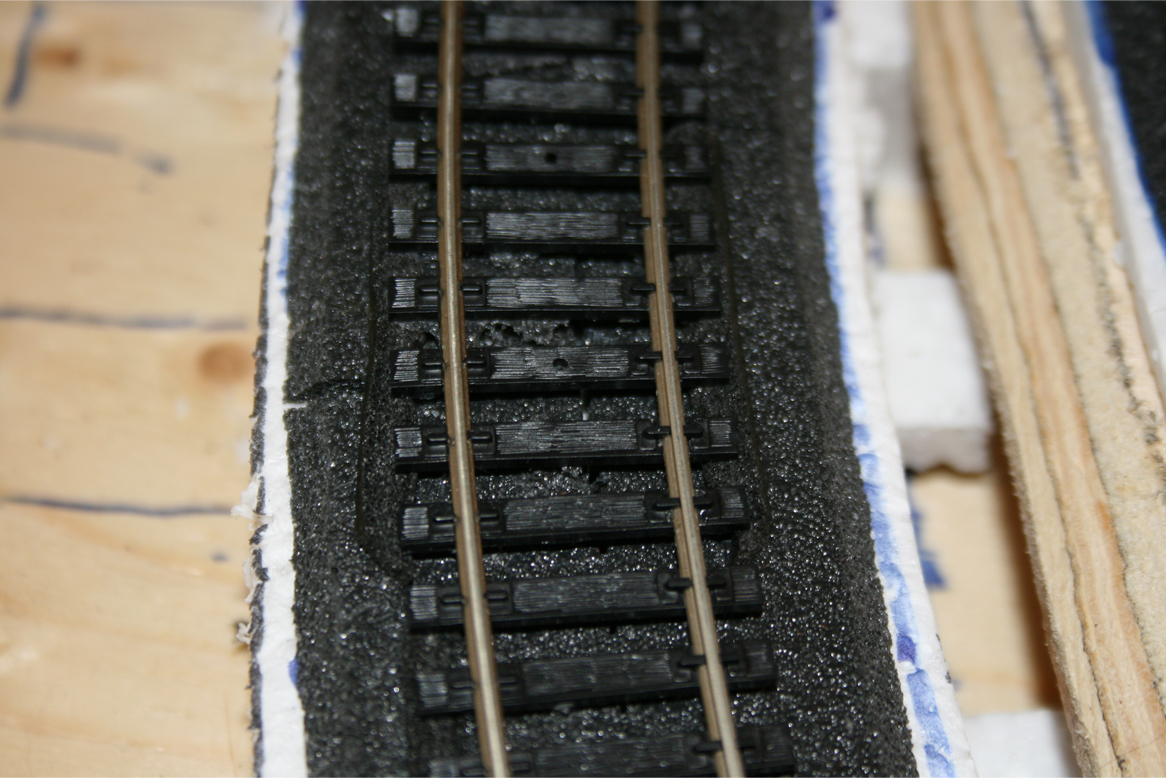

I spent a lot of time running each of my engines back and forth over several

section of problem track, closely watching each wheel to make sure it wasn’t

lifting off the track. I managed to work out all the problem areas I was

having and everything runs a lot smoother. I also had to make a few small

adjustments with my wiring, but nothing major.

I am now into the planning stages of building the actual ground terrain

and elevations of my layout, which I hope to have completed by the end of

May. I’m also trying to find the best way to build the standards for my

trackside signals to mount to.