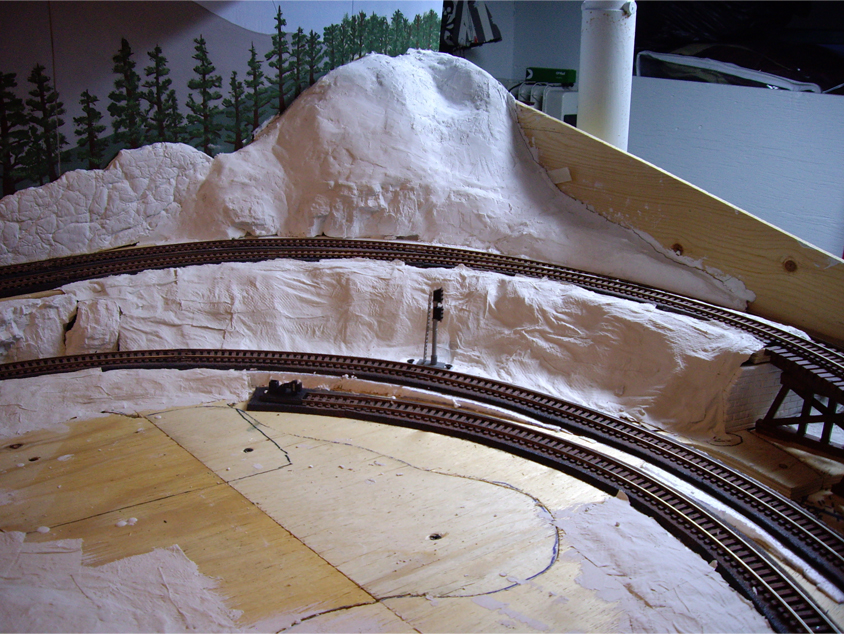

For my terrain structure, I opted to use the hard-shell method. This

consists of cardboard strips, plaster infused paper towels, and a final

layer of plaster. This seemed to be a popular, tried and tested method. The

materials are very cheap and the end results are very effective.

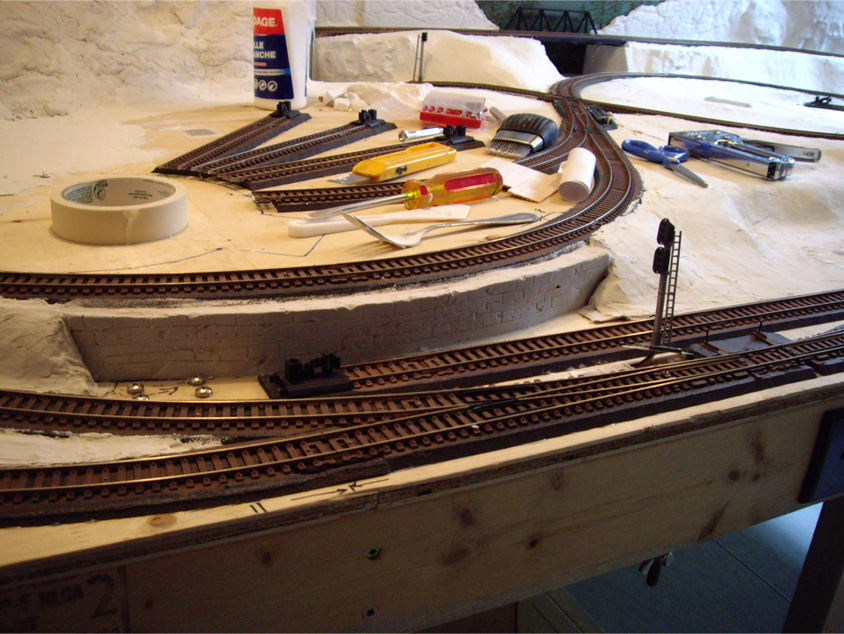

I first started by cutting several different length strips from a cardboard

box, all between 1/2" and 1" wide. The strips were then bent to the desired

curvature and fastened to the benchwork with either white glue and staples.

I spaced each strip about 1" apart. For most of the strips, I didn’t require

horizontal support strips except where the vertical strips were longer and

tended to sag. Crumpled newsprint under the strips also helped with support

in some areas.

I also incorporated some crock outcroppings that I had cast with plaster.

For the more rugged looking terrain features, I used the same crumpled paper

method that I used for my mountain tunnel. For future planned roads, I

simply cut a desired sized piece of cardboard and attached it just as I did

with the other strips, ensuring a smooth grade from the upper level to the

lower ground level.

The next step was to cover the cardboard strips with plaster-impregnated

paper towels. For this, I tore sheets of paper towel into strips at various

widths. Preparing a good mixture of thin and wide strips cardboard strips

makes it a lot easier to cover larger and smaller areas.

I mixed powder drywall compound into a large, shallow container with water.

This took a little trial and error to get the right consistency; if too thin

the paper towel strips will dry and peel and have no rigidity. If too thick,

the paper towel will just rip under the weight. Good quality, brand name

paper towel also helps immensely. I had to keep stirring the plaster mixture

as I worked as the plaster tended to settle to the bottom of the container.

Adding a bit of water to the mixture as I worked will also keep things

flowing.

Once I had found the proper plaster mixture, I dipped in each strip of

paper towel, wiping off the majority of excess plaster from the strips with

my fingers. I then positions the paper towel strips horizontally across the

cardboard strips, overlapping them for added strength. I didn’t worry too

much if the paper towel strips sagged a bit between the cardboard support

strips as this would be leveled off later with the final plaster layer. I

used my fingers to smooth the strips as much as possible.

After 24 hours the paper towel shell was dry and I was left with a rigid,

somewhat brittle shell. I then applied a layer of plaster to the shell. This

adds strength to the plaster shell and levels out any seams or sagging spots

that may have formed. I used a gypsum based plaster but made the mistake of

using a pre-mixed product. This is much more prone to cracking and shrinking

compared to dry mix so, I had to go back and fill several cracks that had

formed. I also cast a retaining wall right in front of the turn table using

a cardboard mold that I made. The wall is cast with plaster of Paris and

detailed with hand carved bricks.

Once the first layer of plaster dried, I spread a second, final layer of

plaster over the entire shell, thicker in some areas to eliminate low spots.

I blended in all of the rock outcroppings and filled in any holes or cracks.

I used a combination of my hands and small plastic spatulas to smooth and

level the plaster layer and blend it with the existing bridge abutments and

terrain. Ground foam and dirt will fill in any deficiencies in the plaster

once it's added. I still have a few things to touch up but I can finally say

that the plaster hard-shell is complete.